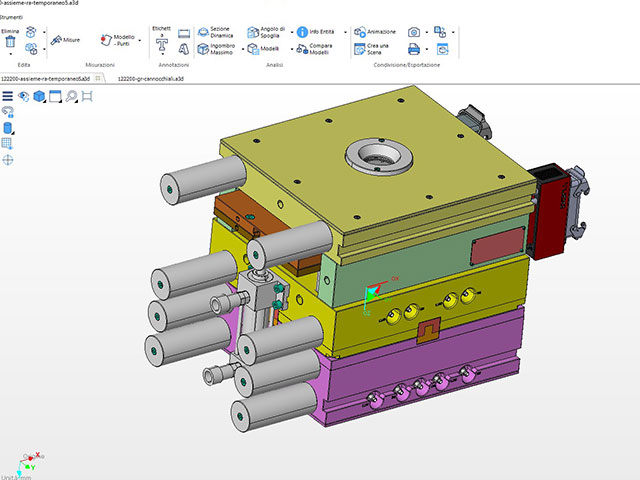

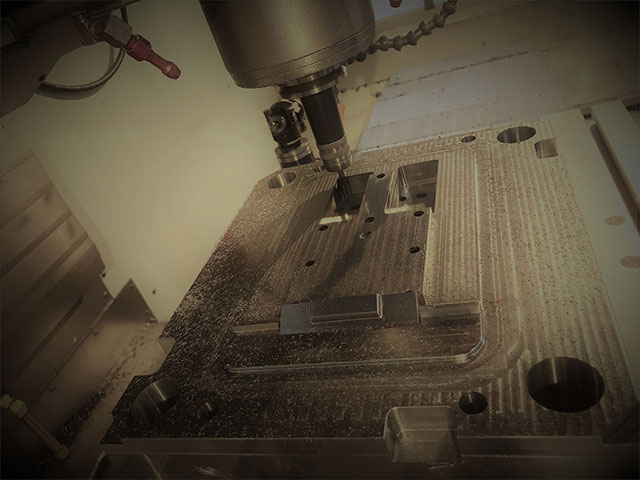

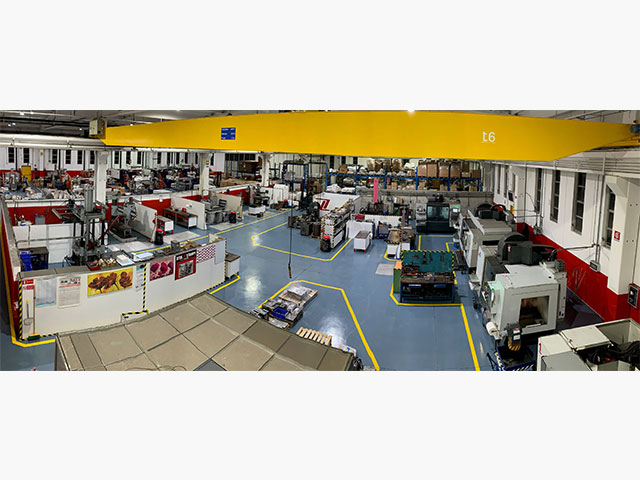

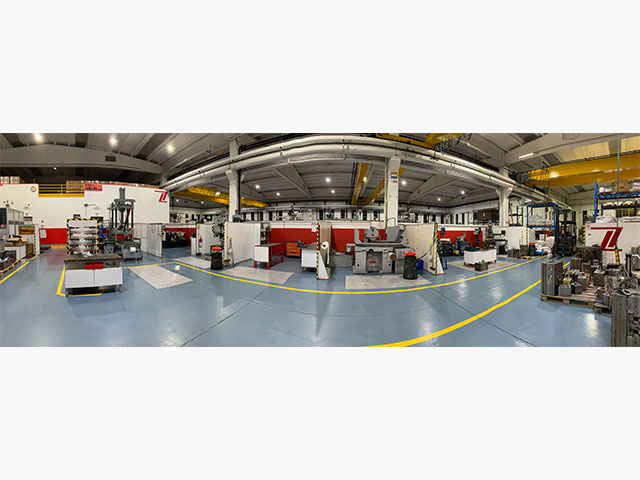

Design and construction of moulds

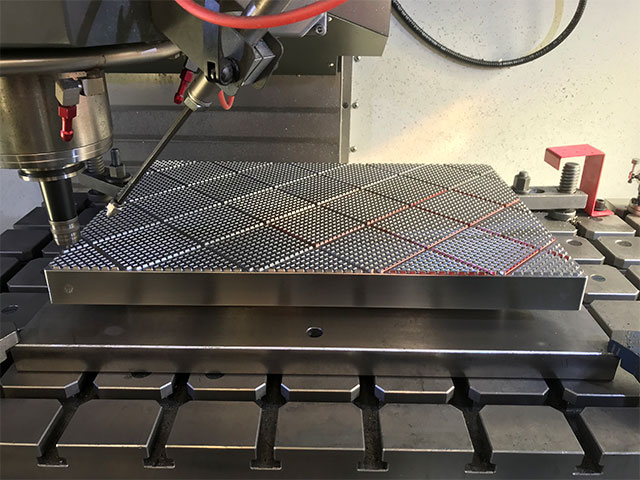

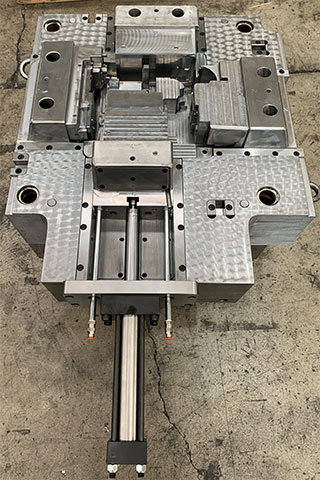

We make about 80/100 small and medium size moulds per year (maximum size 1200 x 700mm, maximum weight approx. 5000Kg) for different areas of use: household electrical appliances, automotive industry, hobbies, displays/promotional articles, furniture, office articles, hospital articles, articles for electric material, household articles and more.

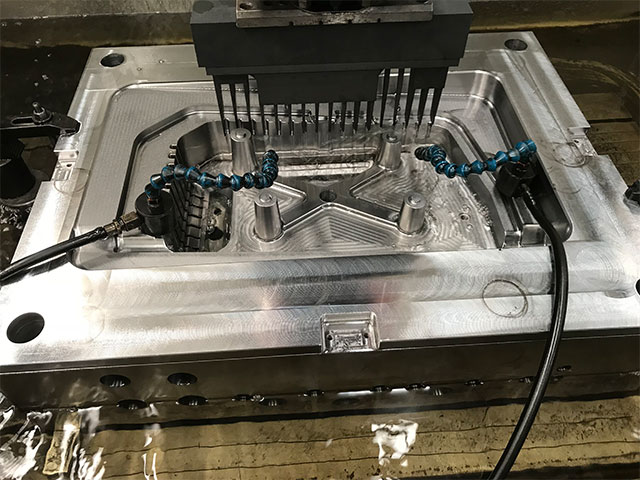

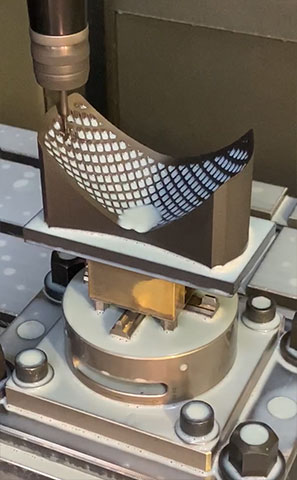

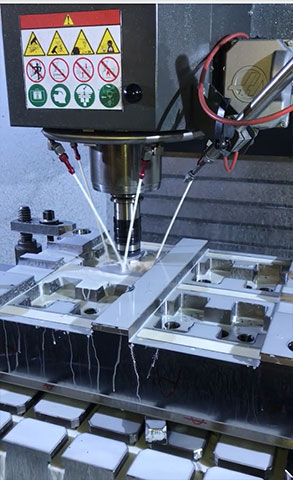

Single cavity, multi-cavity moulds with hot or cold runners (made by us or by the best-known international manufacturers) with mechanical or hydraulic movement, with tempered blocks, with gas assisted injection.

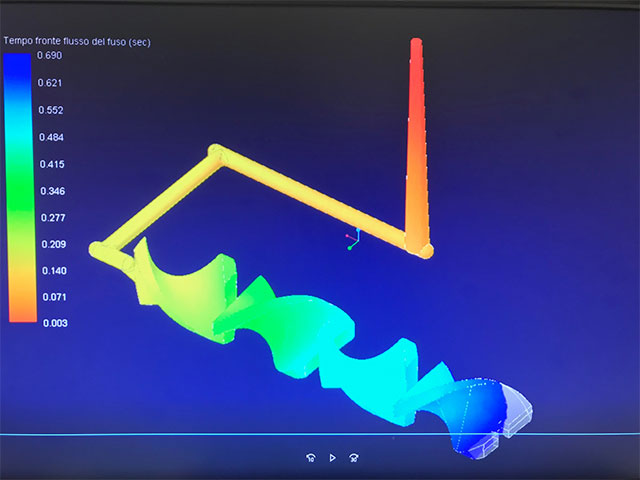

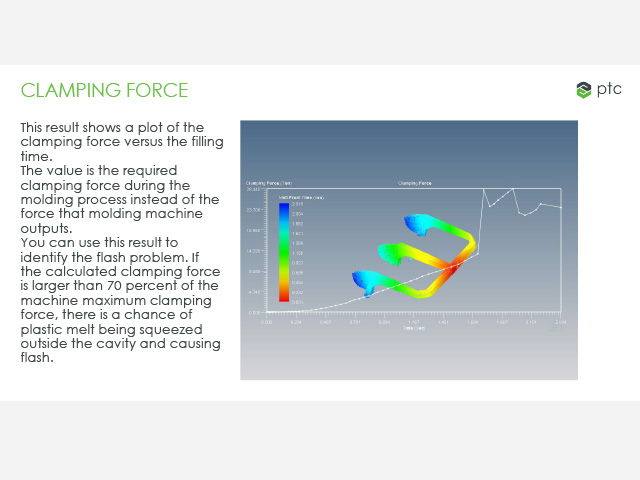

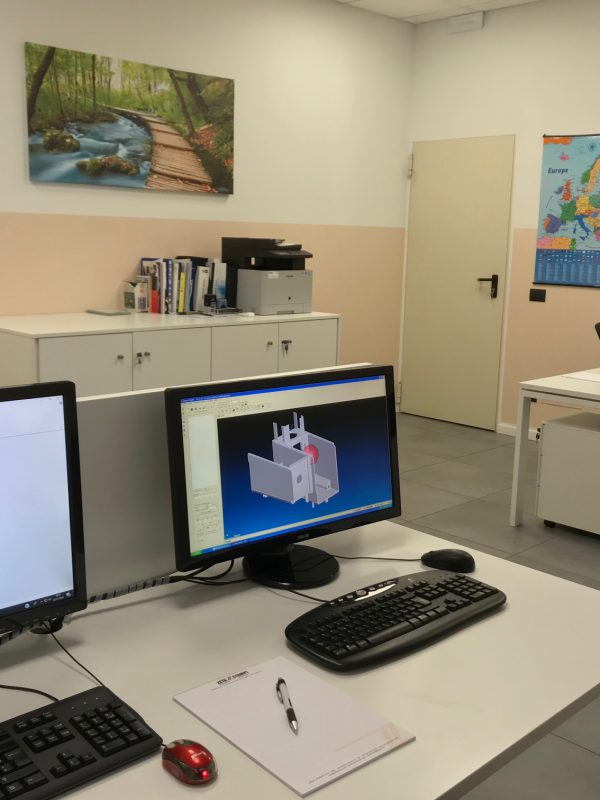

Our designers will be able to suggest the best technical

and aesthetic solutions to achieve a quality article.

Every decision regarding the placement of ejector pins, injection gates, slides, lifters etc., will be shared with the customer as will the entire moulding project.

Should customers not have three-dimensional files of the article available, we are able to make it according to their specifications (co-design) and if necessary provide prototypes in quick time before beginning moulding.